What Should I Consider Before Buying An Email List Of Hematologists? In order to ensure that your list of hematologists is relevant, effective, accurate and compliant with the law, you need be attentive to a few crucial aspects. Here are the main considerations:1. Quality and Accuracy of the DataSource of Information: Make sure that the email list

30 Top Ways For Choosing Devil666 Slot Sites

The 10 Most Effective Tips For Devil666 Slot Indonesian Gambling Platforms Online To Improve Game Variety The choice of games is an essential aspect in deciding on Devil666 Slot Indonesian betting platforms. It can improve the enjoyment of betting. With the wide variety of games available, you will be able to access a wider variety of betting optio

30 Top Suggestions For Choosing 7raja Togel Websites

The 10 Most Important Tips For User Experience For 7rajatogel Indonesian Online Betting Platforms The user experience (UX) which is the key component of any online betting platform, is crucial. It includes everything from website design and customer support, and directly impacts on how enjoyable and successful your betting experience is. For 7raja

30 Great Pieces Of Advice For Choosing IDNPLAY Websites

Top 10 Tips To Help You Choose The Right Game For Your Online Betting Platform In Indonesia Game variety can be a major factor in the improvement of your online betting experience. You will have a range of betting options and an array of games. These are the top 10 suggestions to help you assess the variety of games on ASIAN 2 BET Indonesian bettin

30 Pro Facts For Deciding On TAJIR4D Websites

Top 10 Tips For Online Betting Platforms In Indonesia On Regulations And Licensing When looking at online betting platforms in Indonesia, knowing the regulatory and licensing environment is vital to ensure a safe and legal gambling experience. These are the top 10 tips on licensing and regulation for tajir4d rtp Indonesian betting websites:1. Verif

Rider Strong Then & Now!

Rider Strong Then & Now! Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Jane Carrey Then & Now!

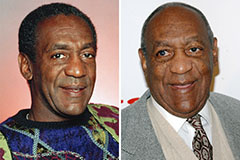

Jane Carrey Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now!